The Ultimate Guide to Choosing the Perfect Gasket Sealant for Any Project

Looking to seal the deal on your next project? Look no further! In this ultimate guide, we'll walk you through everything you need to know about choosing the perfect gasket sealant. Whether you're a professional or a DIY enthusiast, finding the right sealant is essential for ensuring a tight and long-lasting seal.

When it comes to gasket sealants, one size does not fit all. From high temperature applications to corrosive environments, each project has its own unique requirements. That's why we've compiled a comprehensive list of factors to consider when selecting the ideal sealant. We'll cover topics such as material compatibility, temperature resistance, curing time, and more.

With our expert advice, you'll be equipped with the knowledge to make an informed decision that meets your specific needs. No more guesswork or trial and error. It's time to seal the deal with confidence! So, whether you're working on an automotive repair, plumbing project, or industrial application, this guide has got you covered. Get ready to choose the right gasket sealant and ensure a successful outcome every time.

Importance of choosing the right gasket sealant

Gaskets are essential components in a wide range of applications, from automotive and industrial machinery to plumbing and HVAC systems. These vital seals play a crucial role in preventing leaks, maintaining pressure, and ensuring the proper functioning of various equipment and devices. However, the success of a gasket largely depends on the sealant used to secure it in place. Choosing the right gasket sealant is paramount, as it can make the difference between a long-lasting, reliable seal and a costly, potentially dangerous failure.

The consequences of using an inappropriate gasket sealant can be severe. Imagine a leaky engine gasket that allows oil to seep out, leading to engine damage and costly repairs. Or a faulty sealant in a high-pressure system that causes a catastrophic blowout, putting lives at risk. Even in less dramatic scenarios, a poorly chosen sealant can result in constant maintenance, downtime, and reduced efficiency, ultimately impacting the overall performance and profitability of a project.

That's why it's essential to understand the importance of selecting the right gasket sealant for your specific application. By taking the time to evaluate the unique requirements of your project, you can ensure that the sealant you choose provides a secure, long-lasting, and reliable seal, protecting your investment and safeguarding the integrity of your equipment or system. In the following sections, we'll delve into the key factors to consider when choosing the perfect gasket sealant for any project.

Factors to consider when selecting a gasket sealant

When it comes to selecting the ideal gasket sealant, there are several critical factors to consider. Ignoring even one of these elements can lead to suboptimal performance, premature failure, or even dangerous consequences. Let's explore the key considerations in detail:

Material compatibility: The first and most important factor is ensuring that the gasket sealant is compatible with the materials of the components it will be sealing. Different sealants have varying chemical compositions and can react differently with different materials, such as metals, plastics, or elastomers. Choosing a sealant that is incompatible with the materials in your application can result in corrosion, degradation, or even complete seal failure. It's crucial to carefully research the chemical resistance and compatibility of the sealant before making a selection.

Temperature resistance: The operating temperature range of your application is another critical consideration. Gasket sealants are designed to withstand varying degrees of heat and cold, and using the wrong sealant for the temperature conditions can lead to premature hardening, cracking, or softening. For high-temperature applications, such as automotive engines or industrial furnaces, you'll need a sealant with excellent thermal stability and heat resistance. Conversely, for low-temperature environments, a more flexible, cold-resistant sealant may be necessary.

Curing time and speed: The curing time and speed of the gasket sealant can have a significant impact on your project's timeline and efficiency. Some sealants cure quickly, allowing for a faster assembly process, while others may take longer to fully set. Depending on your specific needs, you may prioritize a sealant with a faster curing time to minimize downtime, or one with a slower curing time to allow for adjustments and repositioning during installation.

Types of gasket sealants - silicone, RTV, anaerobic, etc.

When it comes to gasket sealants, there is a wide variety of options available, each with its own unique properties and applications. Understanding the different types of sealants and their characteristics can help you make an informed decision that best fits your project's requirements. Let's explore some of the most common types of gasket sealants:

Silicone sealants: Silicone-based sealants are a popular choice for a wide range of applications due to their excellent flexibility, temperature resistance, and weatherproofing capabilities. These sealants are known for their ability to withstand extreme temperatures, from as low as -60°C (-76°F) to as high as 300°C (572°F), making them suitable for both hot and cold environments. Silicone sealants also offer good chemical resistance and can be used to seal a variety of materials, including metal, glass, and plastic. However, they may not be suitable for applications that require high-strength adhesion or where a permanent, rigid seal is needed.

RTV (Room Temperature Vulcanizing) sealants: RTV sealants are another versatile option, often used in automotive, industrial, and plumbing applications. These sealants cure at room temperature, forming a flexible, durable seal. RTV sealants come in two main types: one-part and two-part. One-part RTV sealants are easy to apply and cure when exposed to moisture in the air, while two-part RTV sealants require mixing of the components before application and offer a stronger, more reliable seal. RTV sealants are known for their excellent resistance to weathering, chemicals, and vibration, making them a suitable choice for a wide range of sealing needs.

Anaerobic sealants: Anaerobic sealants, also known as thread-locking compounds, are designed to cure in the absence of air, making them ideal for sealing threaded fasteners and fittings. These sealants form a strong, permanent bond that prevents loosening and leaks, even in high-vibration environments. Anaerobic sealants are particularly useful in applications where disassembly may be required, as they can be easily broken down with the right tools. They offer excellent resistance to chemicals, solvents, and high temperatures, making them a popular choice for industrial, automotive, and plumbing applications.

Understanding the different applications for gasket sealants

Gasket sealants are not a one-size-fits-all solution. Different applications require specific sealant properties to ensure optimal performance and reliability. Understanding the various applications for gasket sealants can help you choose the right product for your project.

Automotive applications: In the automotive industry, gasket sealants are essential for sealing a wide range of components, from engine blocks and cylinder heads to fuel systems and transmission housings. These sealants must be able to withstand high temperatures, vibration, and exposure to various automotive fluids, such as oil, coolant, and fuel. Silicone and RTV sealants are commonly used in automotive applications due to their excellent sealing properties and resistance to the harsh conditions found in vehicles.

Industrial machinery: Industrial equipment, such as pumps, compressors, and gearboxes, often require robust gasket sealants to prevent leaks and maintain the integrity of the system. These applications may involve exposure to high pressures, corrosive chemicals, or extreme temperatures, necessitating the use of specialized sealants with enhanced chemical resistance, temperature tolerance, and durability. Anaerobic sealants are particularly well-suited for industrial machinery, as they can form a secure, permanent seal that withstands vibration and high-stress environments.

Plumbing and HVAC systems: In the plumbing and HVAC industries, gasket sealants are used to seal a variety of fittings, joints, and connections, ensuring the proper functioning of pipes, valves, and other components. These applications often require sealants that can withstand water, moisture, and temperature fluctuations, as well as resist the growth of mold and mildew. Silicone and RTV sealants are commonly used in plumbing and HVAC applications due to their waterproofing capabilities and flexibility.

How to properly apply gasket sealants

Proper application of gasket sealants is crucial for ensuring a long-lasting, reliable seal. Improper application can lead to leaks, premature failure, and even damage to the components being sealed. Here are some best practices for applying gasket sealants:

Surface preparation: Before applying the sealant, it's essential to thoroughly clean and degrease the surfaces to be sealed. Any dirt, oil, or contaminants can compromise the adhesion of the sealant, resulting in a weak or ineffective seal. Use a suitable solvent or degreaser to ensure the surfaces are clean and dry before proceeding with the application.

Applying the sealant: When applying the sealant, follow the manufacturer's instructions carefully. This may involve applying the sealant in a continuous bead, using a specific pattern, or even applying it to both surfaces being sealed. Be sure to apply the sealant evenly and avoid gaps or air pockets, which can lead to leaks. For some sealants, such as two-part RTV, proper mixing and timing of the application are critical for achieving the desired results.

Curing and assembly: After applying the sealant, allow the recommended curing time before assembling the components. This ensures that the sealant has fully set and developed its maximum strength and adhesion. Rushing the assembly process can compromise the seal and lead to leaks or other issues. Once the components are assembled, avoid disturbing the seal during the curing process, as this can also affect the sealant's performance.

Common mistakes to avoid when using gasket sealants

While choosing the right gasket sealant is essential, proper application and usage are equally critical. Avoiding common mistakes can help ensure a successful and long-lasting seal. Here are some common pitfalls to watch out for:

Inadequate surface preparation: As mentioned earlier, proper surface preparation is key to achieving a strong, reliable seal. Failing to thoroughly clean and degrease the surfaces can lead to poor adhesion, resulting in leaks and seal failure. Always follow the manufacturer's recommendations for surface preparation to ensure optimal performance.

Incorrect sealant selection: Choosing the wrong sealant for the application can have disastrous consequences. Failing to consider factors like material compatibility, temperature resistance, and chemical exposure can result in sealant degradation, embrittlement, or complete failure. Carefully evaluate the requirements of your project and select the appropriate sealant accordingly.

Improper application techniques: Applying the sealant incorrectly, such as using the wrong bead size, failing to fill gaps, or not allowing for proper curing time, can compromise integrity. the seal's Always follow the manufacturer's instructions and best practices for application to ensure a secure, long-lasting seal.

Top brands and products for gasket sealants

When it comes to gasket sealants, there are many reputable brands and high-quality products to choose from. Here are some of the top brands and their standout offerings:

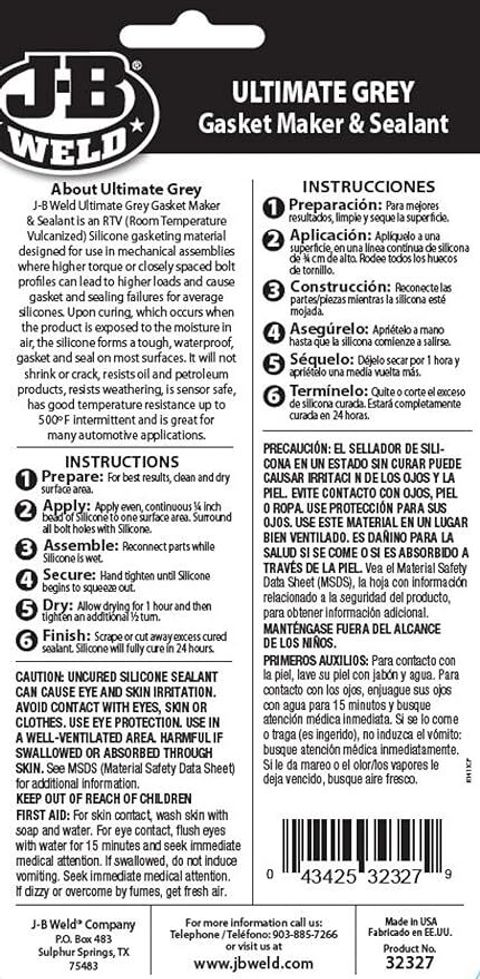

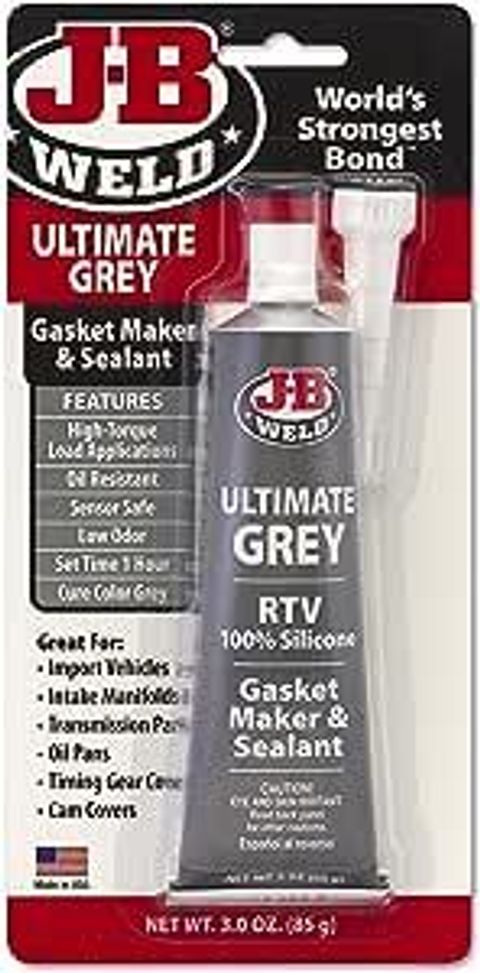

JB WELD: A renowned name in the world of adhesives and sealants, JB WELD offers a wide range of gasket sealants for various applications. Their JB WELD Ultimate Grey, Ultimate Black Gasket Sealant are perfect for the purpose. They are popular choice for industrial machinery, providing excellent resistance to chemicals, oils, and high temperatures.

Where to buy gasket sealants

Gasket sealants can be purchased from a variety of sources, depending on your location and the specific needs of your project. Here are some of the most common places to buy gasket sealants:

Automotive parts stores: For automotive-specific applications, such as engine gaskets, transmission seals, and fuel system components, automotive parts stores are an excellent source for gasket sealants. These stores often carry a wide selection of sealants from leading brands, catering to the unique requirements of the automotive industry.

Hardware stores and Online Stores: These can be purchased from a hardware store in your area. You can order directly from Willpower Group Singapore Pvt Ltd via the online store, also available in Shoppee and Lazada.

Industrial supply companies: For larger-scale industrial or commercial projects, industrial supply companies are the go-to source for high-quality, specialized gasket sealants. These companies often have a more extensive selection of sealants tailored to specific industries, such as manufacturing, construction, or heavy machinery. They can provide expert guidance and technical support to ensure you select the right sealant for your needs. Willpower Group Singapore Pvt Ltd. is one popular go to place in Singapore and South East Asia.